Creating with clay in ancient Greece

The art of shaping imagination with your hands

The

material

Rain and water travel long distances within

the soil, carrying with them elements from the various materials and

soil layers they encounter. This is how clay is created in various

colors, red, yellow-green or brown. When

the rocks consist of pure clay, we get the white clay (kaolin).

Depending on the color of the clay (which becomes apparent after the

pottery is fired) we can distinguish the area from which it comes. After

the clay was mined, it had to be cleaned of small stones, roots,

branches, etc., and then a "mud bath"

followed, that is putting the clay in large

basins of water.

Finishing-Decorating

After being left in the sun to completely dry, the pots were put back on the wheel for details such as their rim and bottom. This meticulous work was indicative of the potter's skill. Handles, reliefs, lids, narrow necks of large vessels, were made separately and connected to the main body of the pot at the end, while the ceramic was still unfired.

Dry it

Drying the ceramic requires great care to avoid losing its shape or developing cracks. It was done in shady and cool areas, with additional attention to the heat, sun, and air of open spaces.Clay requires wet fingers so that it can slide easily, but it must not be completely wet or it will dissolve.

We can therefore imagine the difficulty of creating large or elaborate vases, but also the skill and craftsmanship that was developed by the experienced craftsmen of the time.

Paint it

The pots were painted before firing, but we also have evidence that there was painting after that.

Painting shows no trace of corrections, so it is obvious how skillfull the potter was in a steady hand and free drawing! In drawing horizontal lines or zones, they again used the wheel, other constructions that helped them draw demarcating lines, as well as the compass. The colors they used were natural and resistant to baking. For the chromatic gradation of the forms, they used white, yellow, brown, red, violet. The bright colors were used in smaller details such as wreaths, jewelry, flames and other small decorative details.

In black-figure vases, the vase painter placed his figures directly on the background of the scene and then drew the rest of the scene, while in red-figure vases there was the much more difficult task of first defining all the figures in their negative and then determining the outer outlines.

Bright colors were also applied after the vase was fired, such as brick green, green, light blue, and pink.

The divine protection

The anxiety of people for a good harvest with the help of God is timeless. A good harvest, like a good production in this case, ensured the livelihood of people. The art and skills of the potters were not enough for a loss-free production. In addition, divine protection and support were also needful. For this reason, in Corinth for example, potters dedicated small painted tiles to Poseidon sactuary, with his name engraved on them. On top of that, evil demons could burrow into the kiln to ruin the pottery, so potters would hang a terrifying mask outside the kiln or tree branches, to drive them away. Syntrivos, Smaragos, Asvestos, Savaktis and Omodamos are demons' names in an ancient hymn, which they used to sing at the inauguration of the workshop or at the lighting of the kiln every Spring. Apparently, the work stopped in Winter. From all of the above, we can understand the potters' anxiety and anticipation until the firing of the vessels is completed and the kiln is opened without losses.

During this process, the light trash rose to the surface, while the mass of the clay was channeled into a basin located lower. When the water evaporated, the dried clay could be cut into slabs and stored in a semi-moist condition, so that it could mature. The older and more mature a clay is, the smoother it becomes, and Greek ceramists certainly had great patience! Before processing it, however, the clay had to become even more flexible, and for this reason it was kneaded with the feet.

The wheel

The pottery wheel appeared in Mycenaean times, and quickly became a useful tool for Greek potters. They were made of wood, stone or baked clay and a shaft deeply embedded in the ground. They were rotated by hand (today the wheel can be driven by foot or electricity). When the pots were small, the potter could turn the wheel himself. But for large, heavy wheels were needed, as well as an assistant to whom the master craftsman gave orders regarding the required pace of movement. In order for the pottery wheel to function properly, it must be well centered and its rotating surface well oiled, which is why the craftsman checks them frequently. Homer compares the rhythm of a women's circular dance, to the movement of the potter!

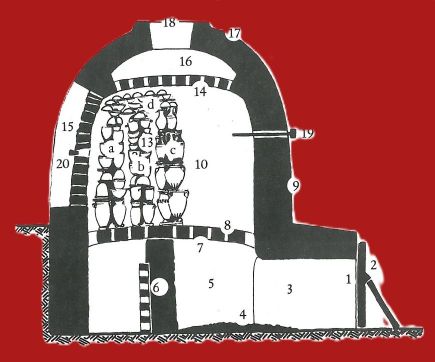

Ceramic kilns

If the process so far seems difficult and demanding, firing was the most difficult process of all, because here all the previous work was in danger of being destroyed. For this reason, in large workshops the master craftsman himself supervises the process, while in small workshops he undertakes it himself. Filling the oven requires enormous skill, since on the one hand they had to take advantage of every available space, and on the other hand the temperature was not the same on each side of it. So filling the oven was done slowly and carefully and often took a whole day! The temperature reached 800-950 degrees Celsius, and it took about 8-9 hours to achieve it. The firing of the vessels began after 6-7 hours and at 500 degrees. Of course, throughout the process, the fire needed to be constantly stoked supplied with wood, so that the temperature could stay at the proper levels. In other words, we have large productions that require a properly adjusted furnace, a small mistake could cost the entire production.